Water tanks are used for storing and preserving water. These tanks are made in various shapes, sizes, and with different materials. They can be utilized in different ways. Water tanks are commonly used in household, agricultural, rural, and other settings. Particularly in areas with low rainfall and frequent droughts, water tanks are essential for optimal water usage. So, if you intend to purchase a water source, it’s better to complete your information about the tank specifications. Water tanks and drinking water tanks have more consumption in central and southern regions of the country. Water tanks and reservoirs have a wide variety. Water tanks and reservoirs can be made of materials such as polyethylene, composite, metal, etc. In the following, we become familiar with water tanks and their types.

What is a water tank?

Water tanks are used for storing water for various purposes. For example, they are used in farm irrigation and drinking water supply. Another purpose of water tanks is to ensure high water pressure. These tanks usually expel water using air pressure, pumps, or gravity. The storage system of these tanks allows water to be drawn from sources such as rain, wells, rivers, etc. and stored

Types of water tanks based on material

Water tanks are used for storing drinking water for residential and commercial establishments as well as rainwater harvesting. They are also used for fire protection, water purification, agricultural irrigation, and other water-related purposes. However, it’s important to know the purpose of each type of tank. Below are the types of drinking water tanks based on the material of their body:

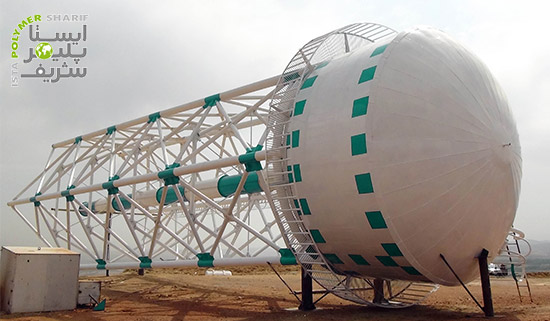

Composite water tank

Composite water tanks, also known as FRP tanks, belong to the category of polymer tanks and are used for storing and preserving water. Composite water tanks have gained a special place in industries today. Composite water tanks are used in industrial water storage, drinking water storage, seawater storage, corrosive fluids, and fuel storage. Composite tanks for drinking water storage are prefabricated or modular. Water tanks can be produced in various shapes and volumes. Modular composite tanks have been most widely used in drinking water storage. Modular composite tanks are manufactured in various volumes and heights depending on the installation location. These tanks mostly have a frame and foundation with a height of 50 centimeters and are belt-shaped. . The advantages of modular composite tanks include easy installation and transportation in hard-to-reach areas and a short installation time.

Panel water tank

Fiberglass panels produced using the SMC process or hot molding are connected to each other by screws, nuts, and metal columns to form the overall structure of the tank. Modular water sources are waterproofed using water sealing tapes. This water source easily accommodates drilling and installation of flanges and fittings, for example, the installation time of a water tank with an approximate volume of 1000 cubic meters from a concrete foundation is about 15 working days. Integrated panel tanks are also widely used for water storage. These tanks have a major advantage over composite water sources. The absence of leaks in these water sources gives them a significant advantage over modular composite drinking water tanks.

Advantages of Metal Panel Water Tank over Welded Tank

Metal water tanks are considered one of the oldest types of water tanks, produced in various forms. When choosing a metal tank, the question arises: What are the advantages of constructing a panel metal water tank compared to a welded water tank, and in what ways do panel tanks excel over welded tanks? Some of the most significant advantages of constructing a panel metal tank compared to a welded water tank can be mentioned as follows:

- One of the most important advantages of constructing a panel metal water source compared to a welded water source is its easier transport and installation.

- Panel tanks are made of panels and components in various dimensions, such as 1 meter by 1 meter. Therefore, the ease of moving the components to all locations, even to difficult mountainous areas, exists.

- Also, there are no welding operations in the construction and installation of panel metal tanks. This is while transporting welded metal tanks is difficult, and their construction takes time due to welding operations.

- The possibility of constructing and building panel water tanks with different and unlimited capacities is another advantage of constructing a panel metal water source compared to a welded water tank. This possibility practically does not exist for welded tanks.

- The possibility of changing the volume or dimensions of the tank is also one of the advantages of a panel metal water tank compared to a welded water tank.

- Space limitation is one of the problems in some places where water sources need to be built. Due to the type of structure, panel tanks can be installed and launched in small and limited spaces.

- The undeniable durability of panel metal tanks is exceptional. These tanks are highly resistant to corrosion and damage. One of the weaknesses of welded tanks is the vulnerability of welded parts. This means that over time, they may be damaged due to factors such as freezing. However, this weakness does not exist in panel metal tanks.

- The ease of fitting connections is another advantage of constructing a panel metal water source compared to a welded water source.

- Cleaning water tanks, especially in drinking water tanks, is important. Cleaning and washing panel metal water tanks are much easier than welded water tanks. Therefore, the hygiene of these tanks can also be considered among the advantages of this type of tanks.

- Another advantage is the desirable productivity, high durability, and no change in water quality of panel metal tanks.

Galvanized Water Storage Tank

Galvanized drinking water tanks and pre-fabricated galvanized tanks or modular galvanized tanks are among the most advanced tanks worldwide. These tanks are highly transportable and have high mechanical resistance. Modular galvanized tanks have no welding on the body and can be easily installed on-site. Galvanized drinking water tanks or modular drinking water tanks have major advantages over composite tanks or GRP tanks or SMC tanks.

Polyethylene Water Storage Tank

Polyethylene water tanks can be produced or built on-site in capacities ranging from 300 liters to 100 cubic meters. These tanks are made in cylindrical and cubical shapes. After polyethylene water tanks, metal water tanks have the highest consumption in various industries. Composite water tanks or GRP tanks are also used today in various places for drinking water storage and firefighting water. Water tanks can be produced as integrated and modular.

Concrete Water Storage Tank

Concrete water tanks are commonly used for industrial water storage and pre-treatment. Concrete water tanks are widely installed on-site. Epoxy coatings, Koltar, and polyurethane coatings are used for waterproofing these water tanks. Polymer tanks are the best types of water storage tanks. These tanks have low weight and high corrosion resistance. Polyethylene water tanks and composite water tanks or GRP tanks are used in this field. Polyethylene water tanks have the capability of designing and building to very high capacities. FRP tanks or composite tanks also have these conditions.

Each of these tanks has advantages and disadvantages, which you can find out by visiting their description page (click on each type of tank above) to get complete and comprehensive information.

Plastic Water Storage Tank

Many people who used to use metal tanks have now decided to replace their metal tanks with plastic tanks. Most commonly, a metal tank is referred to as a galvanized tank because galvanized sheets are used to make this tank. Unlike a metal tank, a plastic tank does not rust. In fact, a plastic tank is a newer generation of a metal tank.

Modular Composite Drinking Water Tank

Modular drinking water tanks, also known as modular tanks or modular reservoirs, are among the newest types of tanks in the water industries and facilities sector. All parts of modular drinking water tanks are prefabricated and designed, and for the installation of these types of water tanks, they are sent to the desired location and bolted onto the desired foundation. Modular tanks come in various materials. Composite modular tanks, metal modular tanks, concrete modular tanks, and plastic modular tanks fall into this category. Depending on the space, location, operational temperature, soil type, wind volume, and potential earthquakes, the type and method of installation of these tanks are determined. Water tank modules are connected by bolts and nuts, and water sealing tapes are used between the modules to prevent water leakage

These tanks are highly portable and can be easily transported over long distances. Modular drinking water tanks can be constructed with capacities of up to several thousand cubic meters. This type of tanks can be easily repaired, maintained, and their volume reduced or increased. Composite modular tanks or modular drinking water tanks have various strengths and weaknesses. Composite or modular drinking water tanks are prone to crack growth and corrosion over time, and the possibility of algae and bacteria growth under the shell. This is while galvanized tanks or stainless steel drinking water tanks do not have this problem and limitation.

Metal tanks have high resistance to crack growth and are very easy to repair and maintain. Metal tanks can complete any cubic-shaped space fully and complement the space perfectly Galvanized tanks do not have environmental pollution, unlike modular tanks or composite modular tanks, and can be recycled after use. Galvanized modular tanks or modular galvanized tanks can have coatings depending on the environment they are placed in to withstand very harsh environmental conditions and prevent heat transfer.

Types of Water Tanks Based on Application

Air Tanks

Another type of water tank is air tanks, which are often used to store water in remote areas such as barracks, companies, residential areas, etc. The price of water tanks in this example is higher compared to previous tanks. In this type of tanks, the tank is placed on a high pole.

Water Storage Tank for Buildings

With the increasing advancements of manufacturers in producing various types of building water tanks you can specify the volume of water source you need to the manufacturer according to your needs Building water sources can be prefabricated or built on-site, and in some cases, due to the large size of the tank, it may need to be built on-site, where you can ask for the most experienced water source sales staff to meet your building water tanks. . You can use various large and small water tanks or horizontal and cubic tanks, but in this case, attention should also be paid to the volume of the water source location.

As mentioned, building water tanks are divided into potable and non-potable categories, which are nowadays sold in bulk and retail in the market, and in fact, they have faced a significant increase in sales volume, mainly due to the recent lack of rainfall and the decline in underground waters. Drinking water tanks can be made of polyethylene, which has less volume and weight compared to galvanized, and the price of polyethylene water source in the market is lower than other building water sources.

Sale of Water Tanks for Buildings

Building water tanks are divided into two categories, potable and non-potable, and can be made of various materials according to your needs.

Materials Used for Building Water Storage Tanks

Several raw materials are used to make suitable water tanks for buildings, such as galvanized tanks, composite tanks, concrete tanks, etc. each of which has its own unique features and characteristics that should be considered when ordering and its performance in the building

Types of Water Tanks Based on Appearance

Common shapes of drinking water tanks include cylinder, square, rectangle, hexagonal, and octagonal. The top and bottom of water tanks also vary depending on their functionality. For example, conical tanks, resembling a funnel, allow the contents to flow quickly to the bottom of the tank and facilitate drainage. Water tanks are also available in different capacities in terms of liters.

Water tanks of various sizes are available depending on their intended use. Some smaller tanks can be used for personal and household purposes, with sizes reaching approximately 140 liters. Larger water tanks can hold significant amounts of water, typically up to 30,000 liters or sometimes even more, depending on their capacity The choice of tank size depends on the amount of water needed and the intended use.

Cubical Tank

Cubical water tanks have many advantages, leading to increased sales of these tanks. One of the advantages of cubical water tanks is that the space they occupy relative to the water they store is higher than cylindrical water tanks.

Horizontal Tank

Among the Ista Polymer Sharif manufactures horizontal tanks. These tanks can be made of various materials. Horizontal tanks are very suitable for storing water with a large volume, as they allow for better distribution of high water pressure and prevent tank damage due to excessive pressure.

Vertical Tank

Another type of static tank produced by Sharif Polymer is vertical tanks, which can be used for water storage and preservation. Vertical water tanks are made cubical or cylindrical based on customer needs.

Types of Water Tanks Based on Location

Both underground and above-ground tanks perform the same function but have different locations. Each has its own advantages and disadvantages, and the choice between the two depends on various circumstances:

Above-Ground Water Tank

These tanks are stored above the ground surface, are inexpensive, and easy to install and maintain. They are also easily identifiable in case of any problems. However, they occupy space and are more exposed to severe weather conditions (sunlight and storms) and other damages.

Underground Water Tank

Underground tanks are stored beneath the ground surface and are well protected against cold or hot weather and other damages. These tanks are also safe from fluctuations. However, their installation and maintenance are very difficult, especially since there is no visual way to detect damage.

Points to Consider When Constructing an Underground Water Tank:

Constructing a groundwater source to collect rainwater and preserving it for various uses is essential.

-

- In various locations, water sources and tanks are used for the cultivation of crops. Groundwater sources that can be collected and used include underground water. Access to these sources and proper maintenance is one of the most important activities in this area.

- Groundwater sources have important uses at different times. These sources are also called buried tanks.

- It is better to store rainwater during rainy seasons for use when needed. That is, to optimally use these water sources, they are created and used when rain is not available.

- In various agricultural fields and places where there is water scarcity, the existence of these tanks is the best way to store the necessary daily water.

- the Corrugated reservoir or the same reservoir is an example of this source which has important performance . the other material is galvanized , and they are made and maintained depending on the type of consumption .

- In various agricultural fields and places where there is water scarcity, the existence of these tanks is the best way to store the necessary daily water.

- Underground water tanks are made of different materials, including concrete, polyethylene, and galvanized steel Currently, more polyethylene is used.

- Farmers and gardeners are better off considering the construction of underground water sources to supply their daily water needs and thus make their work easier. This prevents water loss from rain and is the best way to use it.

Applications of Water Tanks

When choosing a water tank, it is better to complete your information about the applications of these tanks. Below are the uses of drinking water tanks:

Agricultural Irrigation

If you grow fruits, vegetables, or anything else, having water tanks to store water in your garden is very important. For those who depend on water, it is very important that their crops grow properly. The size of the water source depends on the amount of water you use and the space you have to store the tank.

Emergency Situations

Emergency use of water tanks includes extinguishing fires. If something catches fire, you should not be left without water. Water tanks are excellent for this purpose, and it is strongly recommended to have a backup tank if your main tank runs out. However, for small fires, having a fire extinguisher is also excellent.

Drinking Water

While drinking water from a bottle is perfectly natural, it is not always something everyone has access to, especially if they live in an area where they can get water from. Having a water source helps you make sure you always have good drinking water when needed.

How to Install a Water Tank

The principles of installing a water storage tank are very simple, and you connect it to a water source and then to your desired destination. However, the complexities of installing them depend on the type of tank being installed, where the water comes from, and what it is used for.

In general, the following steps are taken to install a water storage tank:

- Installation of base or foundation: The tank must be placed on a firm, flat, and relatively smooth base (whether above or below ground). However, if you are installing an underground tank, you need to drill a hole larger than the size of the tank.

- Installation of overflow pipe: This pipe allows excess water to exit the tank if necessary. Some tanks already have this installed, while others may need to be installed.

- Connection to the water tank: Depending on the type of tank being installed, this task may be more or less complicated.

- Installation of filters: You need to consider how water enters the tank in terms of pumps and pressure and also the necessary filters. For example, if you are harvesting rainwater for irrigation, you need a simple filter to remove debris, but if you are installing a drinking water tank, you will need a more complex filtration system.

- Pressure adjustment: Depending on the tank being installed and its mechanisms, you need to consider the pressure inside the tank and how water with the appropriate pressure exits. You may want to rely solely on gravity, for example, or consider a system of air pressure or pumps.

- Connection to outlet pipes: Depending on where you are sending the water, you need to connect the water storage tank to the outlet.

Introduction to Water Tank Construction Methods

The method of constructing a water tank varies depending on the type of tank and whether it is single-layered or multi-layered. Water tanks are manufactured in different dimensions, including single-layer, triple-layer, and multi-layer tanks that are resistant to UV rays, completely anti-silt, algae, and bacteria. Each type of water tank requires its own specialized tools. Water tanks are available in two materials: metal (steel, iron, galvanized, stainless) and plastic (polyethylene and fiberglass) in the market.

It’s important to know that the first step in constructing various types of tanks, whether for water, gasoline, air, or land, is the product blueprint. Engineers go through a standard process to design, model, and ultimately create tank blueprints. The method of constructing a water tank varies based on the type of tank material.

In any method of water tank construction, the most important factor is the material used. The best material used in water tank construction is sheet metal. Constructing a metal tank requires its own specialized tools. Welding, molding, and cutting are necessary for building a metal water tank. Welding galvanized steels is performed using similar methods as non-coated steels. The type of welding will change depending on the desired resistance. Different types of welding such as amp welding, flat welding, or fillet welding are variable. The galvanized tank construction method can be carried out on-site or in the workshop.

It’s worth mentioning that traditional water tank construction methods are not responsive to market needs. Tank manufacturers must produce resilient and modern tanks by utilizing cutting-edge world technology. Ground and aerial water tanks are used for storing and preserving water. The material of ground water tanks is galvanized sheet with various thicknesses. The capacity of ground water tanks ranges from 200 to 250,000 liters. The type of material used in these tanks varies with different thicknesses of galvanized sheets.

Guide to Buying Suitable Water Tanks

In response to the question of which water tank to buy, many factors need to be considered before purchasing a water source. There are two categories of factors general factors that apply to the purchase of any type of tank personal factors that depend on the conditions and space available at the tank installation site.

General factors include the cost-effectiveness of the tank. A tank should be chosen that not only meets the customer’s needs but also has a justifiable price. Nowadays, the use of plastic tanks is more economically justified due to their good resistance and lower prices compared to metals To buy a suitable water source, it’s necessary to examine and be aware of a series of factors, which we intend to address in this section

Step One:

In the first step, you need to determine whether you need a drinking water tank or a non-drinking water tank. The classification of water tanks is as follows:

- Drinking water storage tank

- Non-drinking water storage tank

Step Two:

Selecting the raw materials for making the drinking water tank. At Istapolymer Sharif, we make water tanks tailored to your needs from various materials.

.

Constructing the water storage tank.

Ista polymer Sharif is a manufacturer of water tanks in Tehran and other major cities such as Isfahan, Shiraz, Mashhad, Chabahar, as well as having a history of tank construction in neighboring countries such as Afghanistan, Kabul city, Iraq, Baghdad, and Karbala cities. Tanks can be prefabricated or constructed on-site according to customer needs. Water tanks can be made in various forms, such as underground water sources, aerial tanks, under-stair tanks, cubic tanks, cylindrical tanks, book-shaped tanks, etc. see each repository for a guide to store water and obtain more information on each of the tanks and obtain comprehensive information .

reservoir of water storage in situ

if we want to explain briefly , you may need some conditions , including the large volume of the tank , that your tank should be built in place . in this case , our executive team will be in place and will build your tank in a certain period of time tailored to the volume and materials of your water supply . otherwise , the tank can be built in the ista polymer sharif and it can be carried to the installation site .

Pre-built Water Storage Tank

Another type of tank is pre-built tanks for water storage. The use of these water tanks also has many advantages, which are detailed in the article. Shorter construction time and the ability to build water tanks in different volumes are among the advantages. Composite pre-built tanks and galvanized pre-built tanks are examples of tanks that can be installed anywhere, both inside and outside buildings, and have a longer lifespan.

Which type of water tank material is more suitable?

A water tank should be made of a material that does not chemically react with the solution inside the tank and does not change the color, smell, or taste of the solution (water). On the other hand, measures should be taken to ensure that the tank is algae-resistant. so that it has a longer lifespan The lighter the weight of the tank, the easier it is to transport, resulting in lower costs.

The polyethylene tank from Ista polymer Sharif has less density compared to metal and concrete types. The more uniform the inner surface of the tank and the fewer connections and perforations it has, the more resistant it will be to algae growth. Polyethylene tanks have this feature. Also, due to the absence of seams, there is no leakage Water storage tanks should be resistant to corrosion and decay to have a longer lifespan.

Personal factors depend on the location and existing conditions. This means that depending on the height and area available, a type of tank, whether vertical, horizontal, modular, under-stair, or book-shaped, should be selected. Also, if the environment is very tropical or cold, foam tanks should be used. Today, most home drinking water tanks are made of plastic, and industrial tanks with very large capacities are made of galvanized tanks. The use of concrete and all-metal tanks has become rare due to numerous problems.

Buying Drinking Water Tanks

Today, due to the decrease in rainfall and the drastic decline in underground water levels, the purchase of water tanks has increased significantly across the country. Purchasing a drinking water tank from Istapolymer Shirif can be quite challenging, considering the volume, type of water, budget, and location for tank placement. These tanks have the capability to be produced and built in various three-dimensional volumes and shapes. A large volume of water tanks is purchased by people. Drinking water tanks made of polyethylene are produced using the rotational molding or rotational molding method. These tanks are produced in various volumes and shapes and have captured a significant market share. Buying polyethylene water tanks is also done online, considering the variety of sizes and dimensions.

The features of a drinking water tank should include:

- No change in water taste

- No odor absorption

- No algae growth

- UV resistance

- Multilayered construction

Water tank price

The price of a drinking water tank made of polyethylene varies depending on its location in closed or open spaces. The purchase of metal drinking water tanks takes place at a much higher price difference compared to polyethylene tanks in limited volumes. The price of galvanized tanks can vary significantly depending on the thickness of the consumed sheet and the type of sheet. Generally, the thickness of galvanized tanks starts from 1 millimeter for low volumes and increases to 10 millimeters for larger volumes. The purchase of composite water tanks comes after polyethylene water tanks and metallic drinking water tanks in the market. In general, if tanks are to be used in hot environments and special conditions, composite tanks are the best option. GRP or FRP tanks, due to their high HDT and very high corrosion resistance, are the best option for tropical and humid areas.

Best Price for Buying Water Tanks

The water source is one of the most important factors for storing drinking water. The price of water tanks is influenced by the material, volume, production method, and location. The price of polyethylene water tanks has the lowest price among other tanks in limited volumes. The prices of metallic water sources are in the next category after polyethylene tanks. The price of composite water tanks is the highest among water sources.

Composite water tanks are produced in two forms: monolithic or prefabricated. Modular water tanks or modular water sources are prefabricated panels that are installed on-site on a frame and foundation. Composite panels are produced by the hot pressing process and are transferred to the site after drilling. Modular composite tanks are waterproofed with an elastomeric tape band. Galvanized modular drinking water tanks are also widely used The price of concrete water tanks has the lowest price among tanks.

Water Source Sales

Water source sales and water tank sales are carried out by the engineering and sales department according to the volume and customer needs. Numerous parameters are important for selling water tanks. Water tank sales are initially carried out by the sales engineering department and proposals are made based on the volume and space in which the water tank is placed. Generally, drinking water tanks can be produced in various volumes. Depending on the location of the water source, which may be outdoors or indoors, different products and prices may be available. Polyethylene drinking water tanks have the highest sales among produced tanks up to 15 cubic meters. Galvanized tanks rank next in water source sales. Fiberglass tanks are in the next category of water source sales Today, the sale of polyethylene water tanks and water tankers is done online Corrosion resistance of water sources varies. The sale of water tanks and water sources varies depending on the price of water tankers.

Final Words

As mentioned in previous sections, a water tank is a large container that stores water. These tanks have many applications. If you intend to buy a drinking water tank or non-drinking water tank, you should pay attention to the points discussed in this article. As you know, these tanks are installed in various dimensions and capacities underground or above ground. It is important to pay attention to the application, construction quality, price, and desired store when buying a water tank. If you need consultation for buying a water tank, you can contact Ista polymer Shirif experts at +982144787934 and +982144787935.