Manhole covers are pits used in municipal and industrial sewage networks. These pits, also known as manholes, serve as connection points for sewage networks and access points for water and sewage technicians to repair and inspect sewage pits. Manholes have openings for the entry and exit of people, which are called manhole valves or manhole doors. This article introduces various types of manholes, manhole covers, their properties and characteristics, as well as important points to consider when purchasing manhole covers. Therefore, it is recommended to follow this article to the end for more information about manholes and their accessories.

What is a Manhole Cover (Manhole Door)?

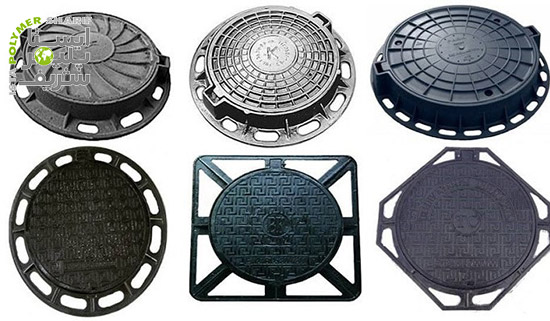

A manhole cover, or manhole door, is located at the outlet of a manhole to prevent people or other objects from falling inside. These covers are designed to facilitate inspection and easy access to sewage systems. Manhole covers come in various types based on the material of their body Cast iron, concrete, composite, polyethylene, and copolymer manhole covers are examples of manhole doors. Polyethylene manhole covers are one of the most common types and usually have a diameter between 50 to 55 centimeters, allowing easy access for individuals to enter the manhole People enter through these covers to inspect and examine the pipes. Manhole covers are produced in various types, each with its own properties and characteristics. Istapolymer Sharif is a manufacturer and provider of various manhole covers and doors in Tehran, Karaj, Mashhad, Isfahan, Shiraz, Ahvaz, Arak, Zanjan, Tabriz, Kish, and other regions of our beloved country, Iran. These covers have various applications, including for water and sewage facilities, telecommunications, electricity, gas, and more.

Types of Manhole Covers

Various types of manholes are installed in cities or public places for sewage, telecommunications, and electricity. Manhole covers are used to prevent people from falling inside and to provide easy access for inspection and repair of manholes. Spatial manholes provide access for individuals to sewage and telecommunications branches.

The types of manhole covers vary depending on the location where they will be used. For example, for accessing underground facilities, covers made of concrete, cast iron, reinforced concrete, concrete composite, and polyethylene are used. In areas with heavy traffic, heavier covers are used to ensure they remain stable when vehicles pass over them.

Composite Manhole Cover

These covers are made of reinforcing fibers of silica embedded within a thermoset resin matrix. As you may know, theft of cast iron manhole covers is very high, making them an unsuitable option. Additionally, concrete covers are excessively heavy. Therefore, manufacturers have turned to producing a product that is both theft-resistant and lighter in weight compared to concrete samples. At this stage, composite manhole frames and covers were produced and introduced to the market.

Nano Composite Manhole Cover

This cover is made of cement. The advantages of the nano composite cover include being lightweight, having fibers with high flexural and compressive strength, and having high resistance to concentrated loads.

Polymer Concrete Manhole Cover

Polymer fibers are used in polymer concrete covers. Polymer is used to increase the cover’s resistance to impact, water penetration into concrete, and abrasion.

In addition to being lightweight, the use of polymer fibers reduces the dryness of concrete, which reduces cracking.

Cast Iron Manhole Cover

Cast iron is composed of alloys such as carbon (6/2%), iron (95%), and silicon (3%). Steel, like cast iron, is composed of carbon but the amount of carbon in cast iron is more than two percent. These covers have long been used as covers for well lids, manholes, telecommunications facilities, water companies, covers sewage and gas . Cast iron manhole covers are popular due to their different mold shapes and reasonable prices.

Gray Iron Manhole Cover

This type of cover is made of iron, which is melted in a furnace and poured into a mold. The advantages of this cover include resistance to impact and gases such as sulfuric acid. The surface of this cover is designed to create friction. One of the weaknesses of this type of cover is the low quality of the manufacturer’s logo and the contents of the client company.

Ductile Iron Manhole Cover

This type of cover is made of unbreakable iron. It has more flexibility and expansion than gray iron. This type of cover is recyclable.

Polyethylene Manhole Cover

This cover is made of a combination of polymer concrete with a cast iron or polymer frame, or a combination of ethylene with cast iron and concrete. Polyethylene manhole covers have a wide range of applications, including in the oil and gas, water and sewage, and petrochemical industries, and are widely used in these industries. The presence of covers in these industries has created problems, such as breaking and corroding. Rusting of these covers is common, so covers that are rust-resistant should be used.

Advantages of Polyethylene Manhole Cover

As mentioned, polyethylene manhole covers have a wider range of applications compared to other types of covers. These covers have many features, some of the most important advantages of using polyethylene manhole covers are highlighted below:

-

- Cost-effectiveness of purchasing polyethylene covers

- High strength and resistance against various impacts and pressures

- Long service life and high storage life with proper maintenance and air circulation conditions in storage spaces

- Excellent chemical resistance against corrosion and weathering factors

- Complete and continuous system

- High surface roughness to ensure safety and prevent slipping

- Quick installation speed and low installation cost

Applications of Manhole Covers

The applications of these covers are determined based on the installation location and the contractor. Manhole covers are used in sewage inspections, municipalities, electricity, telecommunications, water and gas facilities, and oil. Considering their usage, they come in square and circular shapes. The most commonly used sizes are dimensions of 60 and 80 centimeters. The manhole cover is placed at the entrance section of the manhole as a cover. Holes are created on the cover to lift it with a hook. Some manhole covers are used to collect surface water and rainwater and transfer it to the city’s sewage system, which are called stormwater covers. The application of these covers is mostly in municipalities.

This product is one of the best-selling static polymer covers in sewage facilities by Estapolymer Sharif. These covers are made of various materials and can be manufactured according to customer needs. They can also be made in circular, rectangular, and square shapes. They are also available in various colors and can have the logo of the relevant company or organization printed on them.

- Cast Iron Sewer Manhole Cover is made of iron and carbon alloy and can be used for traffic and non-traffic purposes.Its color is gray, and it is usually heavy.

- Polyethylene Sewer Manhole Cover: This cover is made of hard polyethylene and has a lower price and weight compared to the cast iron sample. It can be both traffic and non-traffic.

- Composite Sewer Cover: These covers are reinforced with glass fibers and, despite their low weight, can be very resistant and can be used both in traffic and non-traffic situations.

- Polymer Concrete Sewer Cover: This cover is made of concrete reinforced with polymer fibers, which has better resistance than concrete covers and can be made in various shapes, both traffic and non-traffic.

These covers are made exactly according to international standards and do not create noise pollution. Undesirable odors will not be emitted into the surrounding environment by using these covers, and you can continue your life with peace of mind.

Custom Logo on Manhole Cover

You may have seen logos and specific names on manhole covers. Estapolymer Sharif company will print your logo for free on the cover you have ordered.

Classification of Manhole Covers

These covers, considering the amount of load applied, are classified into six classes.

Class A: Load capacity of 1.5 tons. It can be used on sidewalks.

Class B: Load capacity of 12.5 tons. It can be used in car parks.

Class C: Load capacity of 25 tons. It can be used in places with a distance of less than half a meter from the street.

Class D: Load capacity of 40 tons. It can be used on dirt shoulders and vehicle passage areas.

Class E: Load capacity of 60 tons. It can be used in harbors and ports.

Class F: Load capacity of 90 tons. It is used on airport runway shoulders.

Advantages and Disadvantages of Various Manhole Covers

Each type of cover has its advantages and disadvantages. For example, cast iron covers are prone to rusting and ultimately corroding due to low resistance to chemicals and exposure to sewage and rainwater. As a result, their service life is short. They are also vulnerable to heavy weights.

Concrete manholes are also very heavy and do not have good resistance to chemicals, and are sometimes vulnerable. To increase the resistance, composite covers are reinforced with composite fibers, which are also called polymer concrete covers. However, most of the explanation will be dedicated to the new generation of these covers, namely composite manholes.

FRP Composite Manhole consists of fibers reinforced with resin. Resins such as saturated polyester and fibers like glass and quartz are materials used in the construction of FRP manholes. Due to the arrangement of fibers in one or two directions, it possesses high resistance to stresses and is very durable while being lightweight. Moreover, the nature of polyester and other polymeric resins makes it highly resistant to chemicals, water, and moisture. It has the ability to withstand very high loads but its construction is somewhat complex.

A composite manhole or telecommunication chamber is one type of composite valves used for easier access to telecommunication systems, sewage, fiber optic networks, electrical cables, etc.

What is a manhole?

In the past and even now, some facilities are inevitably installed underground. Therefore, there are tunnels and small and large pits underground which accommodate facilities such as telecommunications, electricity, water and sewage, oil and gas, etc.

For periodic inspections and maintenance of these facilities, small pits are dug. . If the size of it is large and allows human entry, it is called a manhole meaning a man-sized pit, and if the pit is smaller and only allows viewing the facilities or access by hand, it is called a handhole, meaning only hand access is possible and human entry is not possible.

The number of these inspection pits sometimes becomes large and therefore, to prevent incidents and damages to people, animals, vehicles, etc. it is necessary to protect these manholes or handholes with protective covers called manhole lids.

The size and dimensions of the manhole determine the size and dimensions of the manhole cover. These covers can be made circular, square, or rectangular. Manhole covers are made of various materials. Depending on the materials used, the covers may come in various colors and designs.

Older types of manhole covers were usually made of cast iron and concrete. However, nowadays, with the use of technology in industries, it is possible to produce manhole covers from cheaper but higher quality and more durable materials such as composite manhole covers, compared to older models.

What is a manhole?

In general, a manhole and sewage accessories are a type of drainage system for collecting urban and industrial sewage, which are created along a sewer line with equal distances. In fact, it can be said that a manhole is one of the types of equipment in sewage systems that plays an effective and efficient role in collecting sewage. Manholes can be produced in various types and forms. The components of a manhole include the manhole cover, entry pit, work chamber, manhole channel, and ladder.

Types of manholes based on their material

Manholes are divided into various types based on the type of raw materials used in them. Below are the most common types of manholes mentioned.

Polyethylene manhole

These types of manholes are considered one of the most common sewage systems. manholes are highly resistant to sewage pollutants such as various types of acids up to a concentration of 0.99. Polyethylene manholes are classified into two types of single-wall and double-wall polyethylene manholes in terms of construction type. Below is an explanation of each type of polyethylene manhole:

- Single-wall polyethylene manhole: The height of these manholes is set between 2 to 2.5 meters and they are produced with diameters of 800, 1000, and 1200 millimeters. These manholes are designed as rings of 50 and 100 centimeters. Prominent features of single-wall manholes include the process of manufacturing in the factory and preparing the sent projects. This feature will increase the speed of project implementation and reduce costs.

- Double-wall polyethylene manhole: This type of manhole is produced from corrugated pipes with diameters ranging from 800 to 3000 millimeters and can be produced in various heights according to customer request. This type of manhole can also be produced with corrugated pipes up to a height of over 14 meters. Double-wall manholes are transferred to the engineering department after receiving the desired map from the customer and will be supplied to the market according to the resistance and pressures applied to the body and manhole cover.

Concrete manhole:

This type of manhole is another type of manhole that is supplied to the market as precast with diameters of 110 and 160 centimeters. Precast manholes are used to connect lines of pipes connected to each other in sewage and water supply networks. These manholes are also used in telecommunication systems along the routes of underground cable lines. The raw materials used in this type of manhole are brick, cement, and concrete, and they are usually known as traditional manholes.

Brick manhole

Brick manhole, like concrete manhole, is precast, with its primary materials mainly consisting of brick and cement. This type of manhole is mostly known as a traditional manhole. In recent years, due to the cost of installation and operation, the probability of leakage and corrosion against chemical agents, this type of manhole is less used. Generally, brick manholes are mostly used in telecommunication systems.

Application of manhole in sewage collection system

Manholes and manhole covers are used in sewage and water supply networks for various purposes. Some of the most important applications of manholes and their accessories include:

- Manholes and manhole covers allow for inspection, maintenance, and cleaning of sewage collection systems, as well as washing and separation of impurities collected in sewage networks.

- Manholes can be used to change the direction of sewer lines and guide one or more sewer pipes entering from different directions into one direction inside the manhole covers.

- Manholes also provide ventilation for the interior of sewage lines.

- The use of manholes in branch connections of sewer lines is very common.

Installation of manhole covers

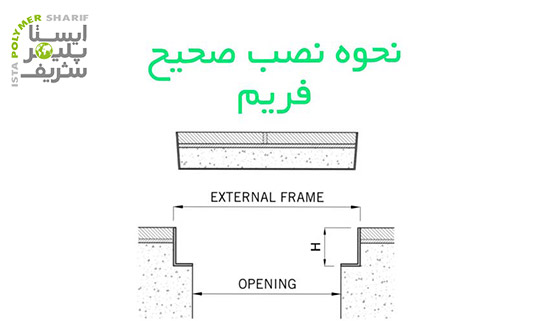

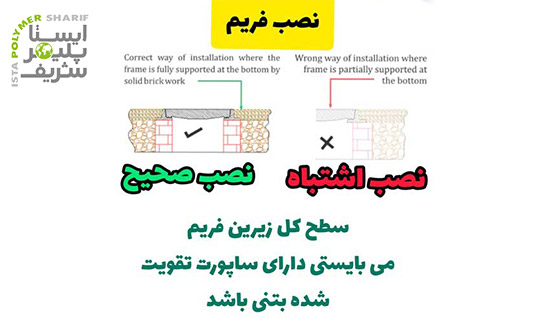

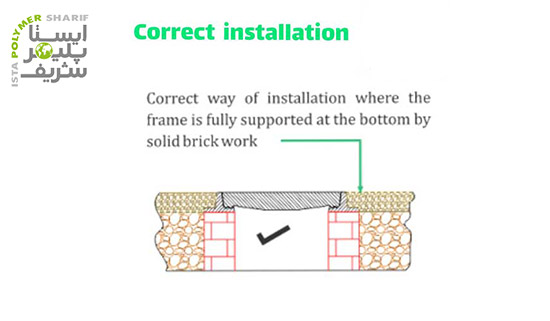

Several processes and operations should be considered during the installation of various types of manhole covers, including:

- First, attention should be paid to the class and shape of the manhole cover.

- The location where the manhole is placed should be properly cleaned and concreted according to the shape of the manhole cover, and the level should be adjusted.

- The manhole cover frame or casing must be properly placed on the cement so that it can easily transfer force.

- Rechecking the levelness of the manhole cover frame is the most important part of leveling the manhole cover.

Proper installation of the manhole cover frame

After performing the mentioned operations and ensuring the correct execution of the cement work on the manhole cover frame, we proceed to install the cover to keep it in place.

Avoid tapping the cover on the frame when placing it.

Price of various types of manhole covers:

The price of Ista Polymer Sharif manhole covers is determined based on the material, quality, traffic, and non-traffic characteristics. Concrete manholes are the cheapest type. However, one of its disadvantages is its heaviness and fragility. Cast iron covers are priced based on their weight and the amount of iron used in them, which increases their resistance. Polymer and plastic composite covers are classified based on the weight passing over the cover, and you need to spend more to bear higher weights. The advantage of polymer covers is that despite their very high resistance to pressure and impact and resistance to corrosion, they are lighter and easier to install.

List of Shreef polymer static manhole cover products.

| Product | Load Capacity | Price |

|---|---|---|

| Circular Valve Diameter 80 with Valve Cover 100 | 40 tons | 02144787935 |

| Circular Valve Diameter 70 with Valve Cover 85 | 25 tons | Please contact us |

| Circular Valve Diameter 65 with Valve Cover 75 | 40 tons | Please contact us |

| Circular Valve Diameter 60 with Valve Cover 72 | 40 tons | Please contact us |

| Circular Valve Diameter 60 with Valve Cover 72 | 25 tons | Please contact us |

| Circular Valve Diameter 60 with Valve Cover 72 | 12.5 tons | Please contact us |

| Circular Valve Diameter 60 with Valve Cover 72 | 10 tons | Please contact us |

| Circular Valve Diameter 55 with Valve Cover 65 | 40 tons | Please contact us |

| Circular Valve Diameter 55 with Valve Cover 65 | 25 tons | Please contact us |

| Circular Valve Diameter 50 with Valve Cover 58 | 40 tons | Please contact us |

| Circular Valve Diameter 40 with Valve Cover 42 | 25 tons | Please contact us |

| Circular Valve Diameter 33 with Valve Cover 42 | 40 tons | Please contact us |

| Circular Valve Diameter 28 with Valve Cover 30 | 40 tons | Please contact us |

| Circular Valve Diameter 20 with Valve Cover 24 | 2 tons | Please contact us |

| دریچه دایره ای قطر 20 با کلاف دریچه 22 | 2 tons | Please contact us |

| دریچه دایره ای قطر 15 با کلاف دریچه 20 | 40 tons | Please contact us |

| Product | Load Capacity | Price |

|---|---|---|

| Square Valve 20*20 with Cover 25*25 | 25 tons | Please contact us |

| Square Valve 40*40 with Cover 52*52 | 40 tons | Please contact us |

| Square Valve 30*50 with Cover 40*60 | 40 tons | Please contact us |

| Square Valve 30*60 with Cover 40*70 | 40 tons | Please contact us |

| Square Valve 30*70 without Cover | 25 tons | Please contact us |

| Square Valve 35*50 with Cover 47*60 | 25 tons | Please contact us |

| Square Valve 35*55 with Cover 40*65 | 25 tons | Please contact us |

| Square Valve 40*40 with Cover 60*60 | 40 tons | Please contact us |

| Square Valve 40*60 with Cover 50*70 | 40 tons | Please contact us |

| Square Valve 40*60 with Cover 50*70 | 25 tons | Please contact us |

| Square Valve 40*75 with Cover 50*90 | 40 tons | Please contact us |

| Square Valve 60*60 with Cover 70*70 | 25 tons | Please contact us |

| Square Valve 63*63 with Cover 73*73 | 25 tons | Please contact us |

| Square Valve 80*80 with Cover 100*100 | 40 tons | Please contact us |

| Product | Price |

|---|---|

| Manhole Cover Diameter 20 Nanocomposite | Please contact us |

| Valve Nanocomposite 32 | Please contact us |

| Valve Nanocomposite 60 for Water and Sewage | Please contact us |

| Valve Nanocomposite 65 for Water and Sewage | Please contact us |

| Valve Nanocomposite 80 for Telecommunication | Please contact us |

| Valve Nanocomposite Roof 60*80 | Please contact us |

How Manhole Cover Prices are Calculated

- The price of Manhole Cover is calculated by multiplying the weight of the valve by the cost of raw materials and adding the profit, production costs, and transportation costs.

- Concrete is the cheapest material for Manhole Cover, while ductile iron is the most expensive.

- The price of a manhole valve varies depending on its dimensions and material.

Manhole Cover Prices in 2022

| Price (Toman) | Valve Class | Valve Size |

| 570.000 | A15 | Oval Valve 28.5*38 cm |

| 1.200.000 | A15 | Diameter 64.5 Valve with Frame |

| 1.270.000 | D400 | Roof Valve 70*50 with Frame |

| 3.900.000 | D400 | SMC Valve with 32.5 Diameter with Cast Iron Frame |

| 940.000 | C250 | 61*51 Valve with Metal Door |

| 1.100.000 | A15 | Square Roof Valve 60*60 with Metal Door |

| 900.000 | D400 | Oval Valve 28.5*38 cm |

| 2.400.000 | A15 | 100*100 Valve with Metal Door |

| 1.500.000 | C250 | SMC Valve with 60 Diameter with Cast Iron Frame 76*76 |

Summary

Manholes are essential equipment in municipal and industrial sewage discharge systems and can be produced in various types. A Manhole Cover is one of the main components of a manhole designed to prevent the fall of people and objects Manhole valves come in various materials such as concrete, brick, and polyethylene, each with its own unique characteristics and advantages. Polyethylene valves, due to their unique properties, are among the most commonly used Manhole Cover. Therefore, paying attention to the features and structure of the valve is crucial when purchasing. When buying a Manhole Cover, attention should be paid to some key points. One of the most important factors in purchasing is the material of the manhole covers. Another important factor is the diameter and dimensions of the manhole valves, which should be considered carefully. Considering the features and applications of the valves is also essential when purchasing these valves. If you need consultation for purchasing Manhole Cover, you can contact the experts at Ista Polymer Sharif at 02144787934 and 02144787935.